A tap cuts or forms a thread on the inside surface of a hole creating a female surface that functions like a nut the three taps in the image illustrate the basic types commonly used by most machinists.

Internal thread cutting definition.

With thread forming the screw itself isn t necessarily modified or otherwise altered.

This is performed by taking successive cuts with a threading toolbit the same shape as the thread form required.

To cut an internal thread you need the following tools.

The original hole is made with a drill or it maybe a cored hole in.

An internal thread can be tapped by hand with hand taps or with a machine with machine taps.

Internal and external threads unlike tapping threads can be milled inside of the hole or on the outside of.

When exposed to the pressure of a machine the thread rolling die creates internal threading.

Find the cutting tool for your specific task andget instant cutting data recommendations go to coroplus toolguide this section covers threading formulas and definitions for how to calculate cutting speed feed rate or any other parameter for your thread turning thread milling or tapping.

For this practice exercise for threading you will need a piece of round material turned to an outside.

Install these inserts into a compatible holder to cut external or internal threads on a workpiece.

Thread forming and thread rolling are processes for forming rather than cutting screw threads with the former referring to creating internal threads and the latter external threads in both of these processes threads are formed into a blank by pressing a shaped tool commonly called a thread rolling die against the blank in a process similar to knurling.

With thread forming a shaped tool known as a thread rolling die is pressed using a machine.

Find the cutting tool for your specific task andget instant cutting data recommendations go to coroplus toolguide this section covers threading formulas and definitions for how to calculate cutting speed feed rate or any other parameter for your thread turning thread milling or tapp.

Thread cutting on the lathe is a process that produces a helical ridge of uniform section on the workpiece.

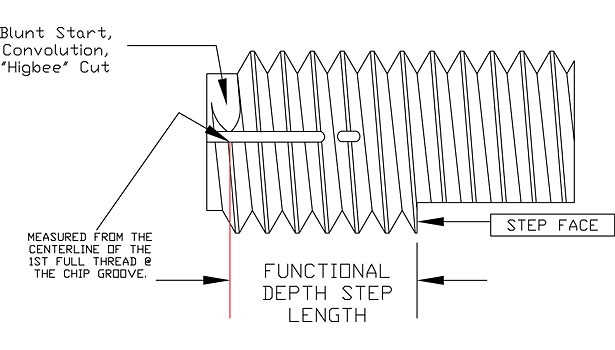

Bottoming tap or plug tap the tap illustrated in the top of the image has a continuous cutting edge with almost no taper between 1 and 1 5 threads of taper is typical.

Cutting large diameter threads with coarse pitches becomes even more difficult.

Internal threading of course is threading found inside of an object.

Thread mills only cut a portion of the circumference at a time which significantly reduces the torque and horse power requirements.